Test paper bucket

Test paper bucketThe test paper barrel and test paper cyli...

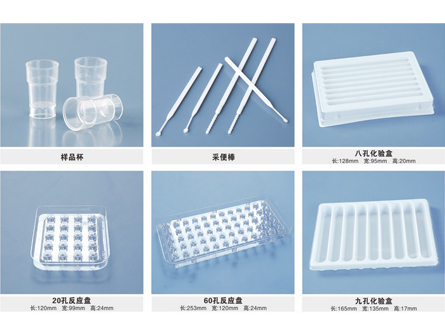

Inspection supplies

Inspection suppliesOur company produces various inspection s...

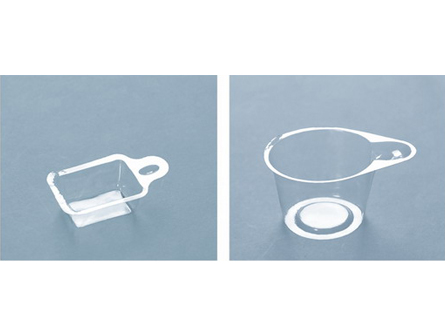

Urinary cup

Urinary cupThe urine cup is a disposable container a...

FOB fecal collection pipe

FOB fecal collection pipeFOB toilet pipes are mainly made of low-d...

FAX:+86-317-4052076

Email:[email protected]

Web:2meiwang.cn

Address:Du Sheng Xiang Xiao Liu Village, Cang County, Cangzhou City, Hebei Province

Current Location:HOME > NEWS > Industry information >

NEWSPreparation of Colloidal Gold

1. The commonly used method for preparing colloidal gold solutions is chemical reduction, which involves adding a certain amount of reducing agent to a concentrated gold solution to convert gold ions into gold atoms. Different types and doses of reducing agents can be used to prepare colloidal gold particles of different sizes. The commonly used preparation methods include self phosphorus reduction, ascorbic acid reduction, trisodium citrate reduction, boot acid trisodium citrate reduction, ethanol ultrasonic reduction, and sodium borohydride reduction. The commonly used preparation method is the trisodium citrate reduction method: heat 0.01 chloroauric acid solution to a boiling plant, stir while adding 1% trisodium citrate aqueous solution, and continue heating until the color of the solution gradually changes from light yellow to a clear and transparent red. This method has a simple preparation procedure and the particle shape and size of colloidal gold are relatively uniform. 2. Colloidal gold labeled colloidal gold protein complexes, also known as colloidal gold probes, are commonly referred to as immunogold when used for immunoassays. The preparation of colloidal gold labeled proteins is essentially the encapsulation process in which biological macromolecules such as proteins are adsorbed onto the surface of colloidal gold particles. Before labeling, the protein needs to be dialyzed with double distilled water to remove electrolytes that affect labeling. Then, a series of dilution methods are used to find a low concentration of protein solution that can stabilize colloidal gold. On this basis, an additional 1% to 20% is added to obtain the optimal labeling amount. Dilute the protein to be labeled appropriately with the optimal labeling amount, slowly add it to colloidal gold, continue stirring for 20 minutes, and then slowly add 10% BSA to the final concentration of 0.5% or 1% (or add 10% PEG20000 to the final concentration of 1%), and continue stirring for 1 hour. Let it stand at 4 ℃ for 2-3 hours or (overnight), and terminate the reaction. After the reaction, centrifuge at 4 ℃ at 10000r/min for 1 hour and discard the supernatant. Suspend the precipitate in 1/10 of the original volume of 1% BSA, centrifuge and wash, add an equal volume of 1% BSA solution, and then add a lower BS buffer containing 0.02% sodium azide to obtain a colloidal gold probe. Alternatively, mix with glycerol and store at 4 ℃ for later use. The labeled immune colloidal gold solution can be stored at 4 ℃ for several months